Design & Development

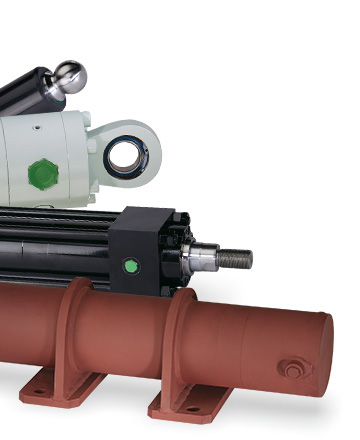

TAL HCD products are designed to endure and perform exceptionally, exceeding customer expectations. Our talented and skilled design and development team strives to consistently provide new and innovative products to customers at optimal prices. The team is constantly working towards developing quality custom cylinder designs that meet the special requirements of our OEM partners and are also efficient to manufacture; a two-fold approach was developed to effectively translate the customers' requirements into reliable performances even in the most demanding conditions.

The design and development team of TAL HCD is equipped with the latest technology like Auto CAD, SolidWorks 3D - Modelling, Finite Element Analysis (FEA) and simulation, design, drafting and adopting ISO/CETOP standards in developing solutions pertaining to hydraulic cylinders and other related mechanisms.

HCD has created designs for more than 60 diversified applications. Our design process involves capturing exhaustive customer inputs, providing design proposals applying Design Failure Mode and Effect Analysis (DFMEA) and process design through Process Failure Mode Effects Analysis (PFMEA), proto development and reviews, extensive validation and type testing, fitment on equipment, function and field trials, customer and field driven Corrective and Preventive Action (CAPA) and finally production release.

Some of the bench mark practices that ensure that our products meet global standards are mentioned below:

Materials

- Proven materials used for cylinder tube, piston rod and child parts

- Raw material for tube, piston rod and child part sourced from reputed mills

- Materials are procured as per ISO/DIN/EN/IS standards

- Materials used include carbon steel, alloy steels, micro alloyed steel, castings, copper, zinc based alloyed material and aluminium castings

- They are corrosion resistant due to chrome plating and nitro carburizing on piston rods

- Special anti-corrosive coating is used for child parts and the plated rods withstand corrosion under NSS testing for 300 hrs

Structural Integrity

- Products are designed to perform throughout their life cycle without structural degradation

- High strength materials are used for special heavy applications

- Designs are analyzed using FEA techniques for optimization to soft validation

- Product undergoes specialized heat treatment for toughening and surface treatments during production

- Customized process design is in place for, induction hardening and quality and testing